| This

Jeep operates far off road and in addition to providing the owner with the ability

to fix anything that breaks when 4-wheeling, the vehicle's welder is used frequently

to rescue others on the trail. Installation is straightforward: An Add-A-Pulley secondary retrofittable alternator pulley is used to drive the Power Generator. The Power Generator is mounted to the vehicle using a ZENA A300 universal mounting bracket which is attached (using 5/16” bolts) to a bracket fabricated from 2”x1/4” angle and 1-1/4”x1/4” bar stock which is attached to the existing alternator mounting bracket. V-belt tensioning is achieved by using an A210 universal extension bracket (which is attached to the Power Generator), a vertical member made from 1-1/4”x1/4” bar stock (which is attached to the fabricated mounting bracket), and two 5/16” turnbuckles in combination. To control engine speed, a RTASC automatic speed control was installed. |

|

|

|

|

|

|

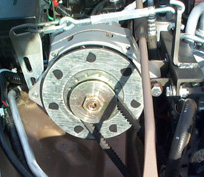

V-belt attachment, Add-A-Pulley to Power Generator, & bracket fabrication details (top view) |

Tensioning system (upright, link, & A210 bracket) / Power Generator to bracket assembly detail |

|

|

|

|

|

|

Belt tensioning system (turnbuckles, A210 bracket, link, & upright) (front view) |

Detail of belt tensioning upright support (welded to bracket assembly) & bracket assembly |

|

|

|

|

|

|

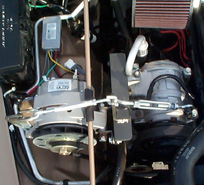

Speed control mount (rear view) |

Speed control to throttle attachment (side view) |

|

|

|

|

|

Belt tensioning system (2 turnbuckles, A210 bracket, chain link, & upright) (top view) |

Completed installation (front view) -- ready to weld! |

| Go to ZENA Web Site Map | View More Installations | Go to Top of Page |

US & Foreign Patents Pending

© Copyright 1998,1999 by ZENA, Incorporated. All rights reserved.

[an error occurred while processing this directive]