|

e-Mail: contact@zena.net |

|

|

e-Mail: contact@zena.net |

|

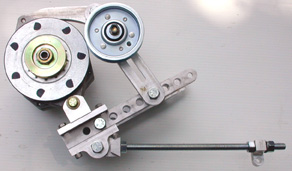

The Main UB2 components -- and what to do with them!

|

|

|

The UB2 is incredibly versatile tool |

|

Base Bars

The two Base Bars are used to connect

the UB2 bracket assembly to the engine which will drive the power generator -- and

to provide primary support for the generator assembly.

Typically, the mounting points for these bars are the existing mounting bolts for the engine's existing alternator. However, any convenient mounting points which are in line with each other and parallel with the engine's drive shaft will work for this purpose.

NOTE: It's also possible for successful bracket attachment when the chosen mounting points ARE NOT in perfect alignment with each other. In these cases, rotation of the assembled bracket assembly will not be possible. Though with careful planning the resulting bracket assembly can be quite serviceable.

In many cases, it will be necessary to enlarge the mounting holes on the rounded end of the Base Bars. It will also be necessary, in most cases, for longer mounting bolts to be used to replace the existing alternator bolts -- to insure adequate thread engagement to insure a secure and reliable connection to the engine with appropriate washers and/or locking fasteners.

When properly mounted the base bars can be rotated to an infinite number of angular positions in relation to the engine and its existing alternator.

|

|

|

UB2 assembly detail -- all components |

|

Base Bar Extenders

The two Base Bar Extenders work

with the two Base Bars to create the two parallel mounting bars which will be used

to securely support and position the Generator Mounting Plate.![]()

Each bar assembly should be connected together with two 1/2” mounting bolts. Depending on the positioning of the two bars in relation to each other, and the mounting holes selected on each bar a number of different lengths can be obtained. In addition, depending on which side of the Base Bar that the Extension Bar is fitted to the generator position can be shifted towards the front or rear of the engine. Also, in this way, the width of the finished Base Bar Assembly can be varied.

If you are using the Tensioning Bars with, or without, the idler pulley the relative front to back position of the Base Bars, when fitted together, will affect the front to rear position of the idler -- and will determine the fit of the Curved Tensioning bar End to the power generator tensioning lug.

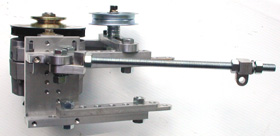

Generator Mounting Plate

This versatile component

works in conjunction with our A300A Pivot Bracket Assembly to provide a firm base

for the power generator and to allow the use of the A300A to precisely adjust the

front to back position of the power generator -- and, therefore, the alignment of

the engine drive pulley (usually a ZENA AAPK mounted on the vehicle's stock alternator's

serpentine belt pulley) with the generator's drive pulley.

This versatile component

works in conjunction with our A300A Pivot Bracket Assembly to provide a firm base

for the power generator and to allow the use of the A300A to precisely adjust the

front to back position of the power generator -- and, therefore, the alignment of

the engine drive pulley (usually a ZENA AAPK mounted on the vehicle's stock alternator's

serpentine belt pulley) with the generator's drive pulley.

In use, the UB2 Generator Mounting Plate is positioned on the end of the base bar extender using supplied bolts, washers, and lock washers.

A300A adjustment is facilitated by a machined recess on the Base Plate which exactly fits the base of the A300A preventing it from moving out of parallel alignment with engine drive components -- yet, allowing easy front to rear motion.

NOTE: The A300A is included as part of the MW150K and the MW150KB truck kits. If you did not buy one of these kits, you will need an A300A.

When the Base Plate is firmly attached to the Base Bars, the entire assembly is drawn into alignment with the engine components, but still (typically) allows rotation of the assembly into an optimal position for generator operation.

Once the UB2 position is determined, the bolts can be tightened to hold the unit in position until additional permanent supports can be attached.

Support

Pivot Point

It is necessary to firmly and securely brace the UB2 assembly to the engine.

To facilitate this, a number of components are provided with the UB2 parts kit. This part is the primary component is this group -- providing an attachment point to the UB2 that can be used with the other components.

|

|

|

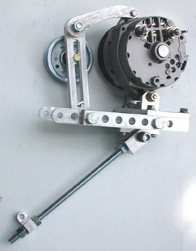

UB2 assembly detail |

|

Straight

Tensioning Bar/Idler Pulley Slide

This component, which may not be used in all applications, can serve a dual purpose. First, the unit, in conjunction with the tensioning bar end can be used to fix the power generator position and/or adjust the generator position to provide a means for tensioning a V-belt (or for adjusting the entire assembly to fit a given V-belt length). The second capability of this part is to provide a means for attaching an idler pulley to the bracket assembly.

Once attached, the idler pulley can be used to provide a primary belt tensioning means and/or to provide a means to insure optional belt wrap around the power generator's drive pulley. When used in this way, belt tension can be reduced somewhat -- improving belt life and reducing periodic maintenance requirements.

The Straight Tensioning Bar/Idler Pulley Slide can be positioned closer to or farther from the power generator by choosing an appropriate mounting position on the base bar assembly.

NOTE: When necessary the bolt holding the lower section of this component can serve a dual purpose -- angular adjustment for the Straight Tensioning Bar/Idler Pulley Slide and/or to fix the Base Bars together.

Curved

Tensioning Bar End

Like its companion component the Straight Tensioning Bar/Idler Pulley Slide this component, may not be used in all applications. Its function is to connect the end of the Straight Tensioning Bar to the tensioning fitting on the power generator. It's curved shape can provide a close fit to the power generator -- even in cases where the power generator is “rocked” away from the engine to a fairly large degree.

NOTE: Depending on generator position, it may be necessary to use some washers to adjust the front to rear position of the Curved Tensioning Bar End to properly fit to the generator's tensioning point.

|

|

|

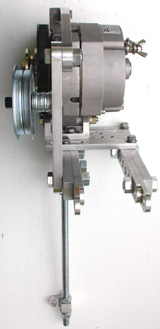

UB2 assembly detail |

|

Threaded Support Rod, Pivoting Support Connector, and “L” Connector Support End

When assembled together and attached to the UB2 assembly these three parts form an adjustable “bar” which can be used to fix the UB2 bracket assembly into it's final position.

The

“L” Connector is designed to act as a sort of universal joint -- typically working

either directly on an existing fixing point on the engine (or its directly attached

components), or with site built components.

The

“L” Connector is designed to act as a sort of universal joint -- typically working

either directly on an existing fixing point on the engine (or its directly attached

components), or with site built components.

In many installations, not all parts will be used. Also, it may be necessary to procure longer sections of threaded rod (available from most all hardware and/or industrial supply outlets).

Idler

Pulley

This component. properly used, can help to significantly improve V-belt performance (drive) and belt life. The Tensioning Bar/Idler Pulley Slide has been milled to accommodate and hold the Idler Pulley's mounting bolt during positioning -- and while being tightened.

However, it's a component which can also be over used -- or mis-used. First, an idler should ALWAYS be used on the “slack” side of the generator's drive pulley (the side of the pulley where the belt ENTERS the drive pulley). If used on the outgoing side, excessive stress is placed on the V-belt and the idler assembly.

Also, too much reverse bending of V-belts can cause overheating and premature failure. If you use the Idler Pulley, take care to use it judiciously in your application.

Optional

Components

The UB2 can also accommodate the use of our AIRT101 Rotary Belt Tensioner (available from our parts dept.).

The AIRT101 is a fully adjustable spring loaded belt tensioning device designed to work with an idler pulley to maintain a constant belt tension (10-30 lb.).

The use of such a device can GREATLY improve belt performance and belt life.

|

|

|

See a typical automotive installation |

|

| Go to Top of Page | Go Forward ----> |

ZENA is a trademark owned by ZENA, Inc. for its welding systems and related products.

US & Foreign Patents Pending

© Copyright 2004 by ZENA, Incorporated. All rights reserved.

[an error occurred while processing this directive]