|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powerful alternators for exotic, high current demand, auto sound systemsGeneral InformationWe get many e-mail's and telephone calls requesting information about high current alternators for custom high-power car audio systems. We even have a standard e-mail response to such inquiries (CLICK HERE TO VIEW THIS) that generally describes our generators and their physical and electrical characteristics.

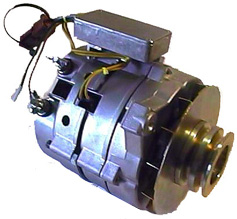

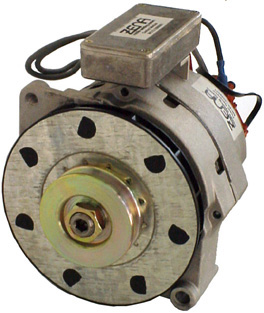

However, their are a few misconceptions that always seem to come up during subsequent discussions of such applications with system/vehicle owners. Therefore, rather than dealing with this information in our FAQ section, we have chosen to cover them here in some detail here. First and foremost, unless you have sufficient battery capacity to dedicate to the audio system, and use the correct type of battery, simply adding a high current alternator WILL NOT solve your power problems.In our opinion, a good definition of "sufficient battery capacity" is: when your fully charged battery (or batteries) can perfectly maintain your electrical system (all vehicle electrical components which share the battery, or batteries, with your stereo components),WITHOUT any additional charging input, for at least 30 minutes (or longer -- based on how long you typically operate the audio system when the car is not traveling, more or less continuously, at highway speeds) -- and,WITHOUT exhausting more than 50% of your battery's storage capacity.Second, remember that automotive alternators DO NOT produce their maximum output until engine speeds are well above idle -- typically 2,000 to 2,500 rpm on the average passenger vehicle.Further, they may produce very little (or even no) power at idle speeds. For example, in stop and go traffic. Third, you must know the peak, minimum, and average power requirements of your stereo system.Without this data you simply cannot properly determine how much alternator capacity that you require. Basically, your alternator should produce AT LEAST 120% of your total continuous power requirement (150% is better) -- at the average engine speed of your vehicle while in use. If it does not, you will likely see your alternator fail prematurely. For example, assuming that you drive at average engine speeds sufficient to produce full power from the alternator, if your audio system demands an average of 100 amps, and if your basic vehicle electrical load is, say, 64 amps (typically 80% of your stock vehicle alternator's rated output), and you have installed a 200AH battery bank, you will need an alternator that can supply at least 300 amps. However, in some cases, average engine speed may not be sufficient to generate full alternator power. In this case, an even larger alternator should be fitted to properly supply the electrical system. In a low engine speed situation like this, to supply your average electrical demand, it might be necessary to install a 400A alternator! Fourth, remember that audio systems have high instantaneous power demands.Alternators can not respond quickly enough to provide power for quick/loud musical passages. A battery can respond quick enough to handle most fast moving audio loads and are key components in an electrical system supplying power to meet the requirements of high power audio systems. However, and this is the fifth key fact,even when charging at a high rate, and at elevated engine speed, automotive electrical generating/supply systems (alternators and batteries), simply cannot respond to the quickest power demands of an audio system. They simply cannot provide additional current quickly enough to supply these requirements on their own. And, when engine speeds are lower, the typical automotive electrical generation equipment frequently cannot even come close provide the power needed. Therefore, for an ideal audio power system, very large capacitors, which can respond to ultra-short term system power demands even faster than a battery, are an absolute necessity. The size of your capacitor (or multi-capacitor array) is determined by your peak power demands. A "Split" Electrical System:Since is it often very difficult, if not impossible to install a single large alternator, often the best automotive audio power supply solution is to "split" your electrical system -- dedicating one or more deep cycle batteries to supply just the high current demand components in your audio system -- charging that battery (or batteries) with a second high output alternator -- and leaving the "stock" electrical system (and engine starting battery) intact. By doing this, ALL of the power produced by the secondary, high current, alternator is available to supply your audio system. This is exactly the sort of electrical system found on the typical emergency vehicle. AND, in most cases, it is by far the least expensive solution. If the installation of a large, properly sized alternator, or a split electrical system (as described previously) is not possible:Consider installing a large battery bank, separate from the vehicle electrical system, to supply your audio system's power amps. Charge these batteries with a conventional battery charger when the vehicle is parked at home. When/if the batteries discharge to 50% (about 12.2 volts) turn off the amps until the batteries can be recharged. While this means that your audio system might not be able to operate at all times, it is much better for your vehicle's alternator, battery, and delicate electrical components (computer chips, etc.) -- which can be seriously damaged by operation in vehicle system that operates with low system voltages. ZENA's Modular Power Generators / Alternators Can HelpRead about choosing a high current alternator, then take your choice from: a 150 amp @ 13-22 VDC unidirectional welding power generator/high-amp alternator (model SR150.12); ora 150 amp @ 13-22 VDC biidirectional welding power generator/high-amp alternator with dual internal rectifiers (model SR150B.12); ora 200 amp @ 13-22 VDC bidirectional power generator/high-output alternator with dual internal rectifiers (model SR200.12); ora 250 amp @ 13-22 VDC power generator/high-output alternator with external rectifier assembly (model SR250.12 and model ER350.12 eternal rectifier); ora 240 amp @ 13-22 VDC power generator/high-output alternator with external rectifier assembly (model SR240.12 and model ER350.12 eternal rectifier); ora 80 amp @ 24-36 VDC high-amp unidirectional alternator (model SR150.24); ora 80 amp @ 24-36 VDC high-amp bidirectional alternator with dual internal rectifiers (model SR150B.24); ora 125 amp @ 24-36 VDC high-output alternator (model SR200.24); ora 140 amp @ 24-36 VDC high-output alternator with external rectifier (model SR250.24 and model ER350.24)' ora 140 amp @ 24-36 VDC high-output alternator with external rectifier (model SR240.24 and model ER350.24).36 and 46 volt models are also avilable. Give us a call to discuss you specific needs. Need even high charging current?ZENA, Incorporated makes the only modular DC power generating units in the world. Multiple compact DC power generating units can be attached to a single driving engine source and be controlled and used together -- just as if they were a single giant alternator. While this technology is normally used to produce large welding currents, ZENA's modular power generators can also be used, in synchronized groups, to efficiently produce very high, well regulated, battery charging currents (for example, from 300 to over 1,000 amps in 12 volt systems) -- serving as ultra high current alternator systems. For example: a 300 amp* @ 13-22 VDC multiple alternator generating system, ora 400 amp* @ 13-22 VDC multiple alternator generating system, ora 500 amp* @ 13-22 VDC multiple alternator generating system, ora 600 amp* @ 13-22 VDC multiple alternator generating system, ora 750 amp* @ 13-22 VDC multiple alternator generating system, ora 800 amp* @ 13-22 VDC multiple alternator generating system, ora 1,000 amp* @ 13-22 VDC multiple alternator generating system, oreven larger charging systems can easily be configured!(* power output in 24-36V electrical systems will be less) Unique Design Features Provide Unique Performance BenefitsThe typical alternator is just not built like a ZENA DC power generator (a key reason why we make this distinction rather than referring to them simply as alternators). Therefore, if supplying a lot of power to a custom audio system and quickly charging batteries is important, a ZENA power generator is an ideal solution. Unlike standard high-amp alternators most of which are designed to produce high currents for a relatively brief period, a ZENA power generator/alternator has been built to produce higher currents continuously --- an absolute necessity for welding, and also a great feature for big audio systems. A number of features make ZENA power generators different from standard high current alternators:ZENA power generators are designed so that they can be controlled with either A or B Circuit (type N or type P) external voltage regulators, or with ZENA's model WC.VR voltage regulator and WC.12 or WC.24 multi-generator controls.Ultra heavy duty output terminals are fabricated from silicon bronze (almost pure copper, but more durable) to insure minimal corrosion in marine environments as well as minimal electrical resistance to the huge charging currents that ZENA power generators can produce (many alternators use high resistance, easily corroded, mild steel terminals on their alternators). AND, these oversize bronze terminals are no less than 5/16" in diameter at any point -- capable of easily handling much larger charging currents -- unlike many so-called high-amp/heavy-duty alternators which only appear to have heavy duty output terminals while internal current handling components are actually far smaller.Generator/alternator output is completely isolated electrically from the generator/alternator case (and, therefore, from the vessel's ground plane). When connected to take advantage of this feature, high amp alternator charging currents can flow directly to the batteries WITHOUT having to also pass through the vehicle engine or frame. This feature also makes connection of generators in series parallel combinations possible.Generator/alternator field circuits are also completely isolated electrically from the generator/alternator case (and, therefore, from the vehicle's ground plane) enabling special regulation systems to be implemented without modification.Rectifiers in all ZENA power generators/alternators are more than double the size required to handle rated output currents, and are also capable of handling exceptionally high reverse voltage spikes. Rectifier heat sinks are equally robust allowing reliable high amp operation in exceptionally hot operating environments.For example, in our SR200 series, which is designed for exceptionally duty, we use twelve (12) individual rectifiers (double the amount found in a typical alternator) -- mounted on double solid copper heat sinks in a separate cooling compartment isolated from the hot internal generating components. (This provides most of the benefits found in an externally rectified alternator without requiring extra engine compartment mounting space or requiring a more complicated installation or extra wiring.Bearings are oversize, and much higher quality than found in a typical alternator -- equally capable of handling high side loads and high temperature operating environments.For example, our 200A alternator's front bearing is large enough for use as a wheel bearing on a small utility trailer!To further reduce bearing wear, and increase service life, rotors are spin balanced and machined to ultra close internal tolerances.Internal wiring, including stator and rotor windings is extra heavy duty -- oversize (stator wire is so large in diameter that windings must be carefully hand fitted to stator laminations), and designed with an insulating system capable of withstanding temperatures of more than 150 degrees Celsius (over 298 degrees Fahrenheit) without failure.All magnetic materials (stator laminations and rotor poles) are built from alloys specially selected for superior magnetic properties.As you might guess, none of these design/construction features have been selected because they are inexpensive. However, cutting costs on items that contribute to product reliability is not something that we do. In fact, our employees get more reward for finding parts with superior performance, reliability, or service life than they do for finding cheaper parts! (In our opinion better quality costs much less than a huge customer service department!) These features do not, however, repeal any laws of physics, nor do they eliminate the necessity to follow good charging system design parameters. You should not scrimp on the selection of proper voltage regulation and/or system protection components for a given application -- nor should you ignore over temperature protection, manufacturer's recommendations for charging current/voltage, proper fusing, charge current limiting/monitoring during bulk charge, etc. These considerations are especially important if your are planing to charge a large battery bank (particularly a large AGM battery bank -- or battery banks made up of a more than three individual batteries wired in parallel) with a relatively small generating system. Such a system would be defined as one where battery capacity in amp-hours (AH) is more than twice the continuous charging capacity of a given alternator in amps. An example of this would be a 200A alternator being used to charge an 800AH battery bank. Three Year Limited WarrantyZENA power generators are sold with a three year limited warranty. And our guaranteed overhaul / rebuilding cost policy further protects your investment in our equipment. Just try to find a high output alternator anywhere with a warranty -- or an overhaul/rebuilding policy like this! Buy risk free using our Online Store -- or call us today to order a unit (615-897-2011).

ZENA® is a trademark owned by ZENA, Inc. for its welding systems and related products.

US & Foreign Patents Pending © Copyright 2000--2018 by ZENA, Incorporated. All rights reserved.

|